An air compressor is one of the most versatile machines you can own in terms of applicability. From nail guns, wrenches, and spray paint guns, all the way to leaf blowers, chainsaws, and inflating car or bike tires, air compressors can be used to power all sorts of equipment for household repairs as well as industrial projects.

Whether you’re into crafts, carpentry, or construction, you know an air compressor is a must-have device in your workshop. Unfortunately, you also know how notoriously loud these things can get, and like all users of the machine, you probably wish it wasn’t so noisy!

Today, we’ll be tackling this issue and telling you exactly how to quiet an air compressor. So let’s not waste any time and get started!

How does an Air Compressor Work?

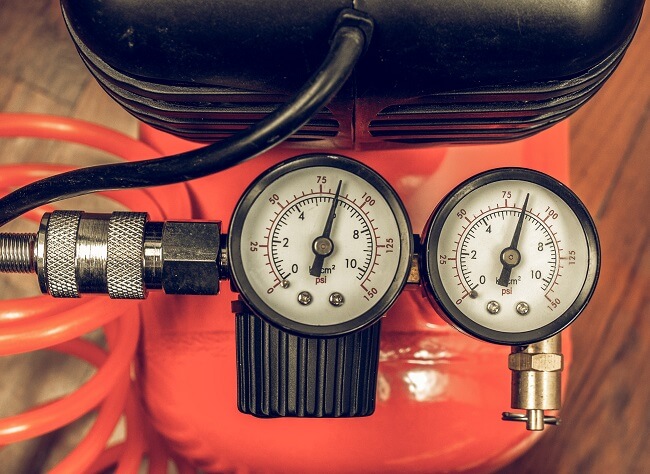

Utilizing a gas/diesel engine or an electric motor, an air compressor converts power into potential energy through numerous mechanisms. This potential energy is stored in the form of pressurized or compressed air, which is entered under force into a designated tank, elevating the pressure until the machine reaches its maximum capacity.

Once the limit is achieved, the air compressor will shut off, keeping the pressurized air inside and waiting for your say-so. When the time comes, the machine will release the stored air, converting potential energy into kinetic energy, which is the energy that ultimately runs all the various equipment.

This entire process includes several factors that contribute to the noisy operation of air compressors.

Why are Air Compressors so Loud?

Air compressors noise is impacted by a number of different factors:

1. Size & Type of the Compressor

Obviously, the size and type of your air compressor have a direct effect on the amount of noise it can generate.

If you own a larger air compressor, this means it’ll be sucking in more air, so it’ll require an engine with a higher power to efficiently pressurize the air. The bigger the compressor, the more powerful the motor, leading to a louder operation.

That being said, there are some types of air compressors designed in a special way to run as quietly as possible.

2. Produced Vibrations

It’s pretty normal for air compressors to produce vibrations, a lot of them at that. However, these vibrations aren’t actually the noise source, but when you add in certain types of surroundings, things can get very loud!

For example, if your air compressor is sitting on top of a shaky or weak surface, it’ll make a lot of noise.

Similarly, if the compressor contains hollow or shallow parts, vibrations will cause more noises to be heard.

3. Placement

Following up on the previous point, the placement of your air compressor can significantly increase the noise you’re hearing.

Besides shaky and weak surfaces, certain types of flooring such as hardwood and concrete tend to intensify the produced noise by creating echoes.

To minimize such an effect, make sure you’re using some kind of soft flooring that’s able to absorb some of the vibrations, for example, a rubber mat or an old rug. This surface should also be sturdy and stable.

4. Air Intake

You know when you turn on a vacuum cleaner and it makes this loud noise as it sucks in the air?

Well, that’s just about what happens in an air compressor, particularly at the intake part of the machine. In fact, the air intake is considered the loudest component of a compressor.

5. The Exhaust

The air exhaust is probably the second loudest component of an air compressor, right after air intake. All the byproducts resulting from the operation of your compressor are discharged through the machine’s exhaust portion, generating lots of noise in the process.

6. Construction Material

Finally, it shouldn’t really come as a surprise to you that materials used in building an air compressor have a huge impact on the amount of noise it makes.

If a compressor is constructed out of low-quality thin materials, then it’s more likely to produce louder noises.

On the other hand, air compressors made of high-quality dense or thick materials aren’t nearly as noisy.

Additional Reasons

Other than the major reasons we mentioned above, there are additional potential reasons for the noises made by your air compressor including:

- Broken thermostat (clicking noise)

- Incompatible starting capacitor (humming sound)

- High internal pressure which could be dangerous (screaming noise)

- Loose screws during mounting (object rattling sound)

- Loose internal components (banging noise)

- A leak from the refrigerant (hissing sound)

Remember, always listen carefully to the type of noise and where it’s coming from so you can better identify the source of the problem.

How Loud can an Air Compressor get?

After discussing all the common reasons for the noises produced by an air compressor, you may find yourself wondering just how loud this machine can get. Well, to answer such a question, we’ll have to use the decibel scale.

If you’re not already familiar, a decibel is a measurement unit that expresses how loud a certain sound is. Humans can hear sounds starting from 20 decibels, while the noise of normal conversation is 60 decibels.

As for air compressors, the most common sizes of 1 HP (Horse Power) or less generate noise levels between 75 and 90 decibels.

Compressors specifically designed to deliver quiet performance produce noise levels no more than 75 decibels, they can even go as low as 40 decibels.

To give you a better idea of how loud these are, an 80-decibel model is four times as loud as a 60-decibel compressor.

Noises above 85 decibels are harmful, they can cause permanent hearing damage through continuous exposure.

This means loud air compressors are definitely not suitable for a home environment. Even for work settings, the OSHA (Occupational Safety and Health Administration) issued stern requirements to protect workers from occupational noise-induced hearing loss by making equipment less noisy than 85 decibels.

How to Quiet an Air Compressor?

If your air compressor is too loud, here are 7 ways to help you make it quieter:

1. Reduce the Air Intake

By now, you should recognize that the air intake of an air compressor is the loudest component of the machine because of the noises produced by the entering air. So it makes sense for our solutions to deal with the intake first.

There are several tweaks you can do to your air compressor’s intake so it makes less noise such as installing a muffler or extending it to the outside.

Install a Muffler

Attaching a muffler or a silencer on the air intake pipe is one of the most reliable methods of quieting down an air compressor. These handy gadgets typically consist of 2 parts: an air filter and a silencing tool.

Once installed, the incoming air passes through tubes made of sound-dampening materials, significantly reducing the amount of noise resulting from the rush of air.

The incoming air also travels through an integrated filter without having its flow rate negatively affected.

If you decide on installing a muffler, make sure you carefully select the correct pipe thread size for the compressor’s air intake head. Only a suitable fit will grant you the highest degree of sound muffling without limiting air intake flow.

Keep in mind that you can use a larger muffler in case you can’t find your specific intake pipe size, however, you should avoid installing one that’s smaller or it’ll restrict the incoming airflow.

Silencers are usually available in standard MPT (Male Pipe Thread) sizes including ¼ inch, ⅜ inch, ½ inch, ¾ inch, 1 inch, and so on.

Get A Longer Air Intake Pipe

This method is another play on the air intake system, where you can actually extend the intake component and move it to the outside so that noise is transferred somewhere else instead of the inside of your house or workspace.

Of course, this doesn’t make the actual machine itself quieter but it simply takes the problem away from your ears to a more secluded and spacious place where the air is sucked from an open area rather than a confined room.

This is also an excellent option if you’re on a budget and can’t afford a silencer, because it doesn’t require expensive tools or resources. All you really need is a long rubber hose or tube as well as a bracket.

First, you’ll have to attach the rubber hose to the air compressor’s intake and make sure the connection is very tight. Now, you want to install the bracket and secure the tube in place so it won’t detach or break.

Once everything is ready, just grab the free end of the hose and put it in a suitable location outside where no one will be bothered by the noise. Be sure to properly fasten the intake tube in its new spot.

Depending on the layout of your house, you may need to drill a hole or use an already existing one for the intake hose to run through reaching the outside.

2. Use Rubber to Dampen Vibrations

Rubber is well known for its sound absorbing and muffling abilities. This means it can easily reduce the noise made by your air compressor by absorbing vibrations, shocks, and impacts to keep their sound from spreading.

You can use rubber to quiet down an air compressor either by installing rubber grommets on the machine’s motor or by applying rubber mounts on the floor where it sits.

Rubber Grommets

Thick rubber grommets are an excellent way to turn down the noise produced by the motor itself. When you turn the compressor on, these grommets will absorb the vibrations of the motor so you won’t be hearing them as much.

Rubber grommets come in packs of various sizes to fit as many motor sizes and types as possible. Additionally, you can use these grommets for other projects after you’re done with the compressor.

Rubber Mounts

Rubber is also a fantastic choice for floor isolation. It keeps the compressor’s body from repeatedly coming in contact with hard surfaces and making noises every time there’s an impact.

You can place rubber mounts or mats underneath the compressor and they won’t even cost you very much.

3. Wrap the Compressor’s Body

This is a more basic yet somewhat popular technique to quiet an air compressor, especially among budget-conscious owners.

You can do it by wrapping the entire body of your compressor with either carpet or some sort of sound dampening mat. This will help muffle the sound of vibrations generated by the machine while minimizing its contact with surrounding surfaces for extra noise reduction.

If you’re looking to cut down on costs, you can use old carpets. However, both options are fairly easy to find online.

4. Put the Compressor in a Soundproof Box

One of the most effective ways to quiet an air compressor is, of course, putting the machine inside a soundproof box. Actually, you can build a soundproof box for your compressor right at home!

First, you want to carefully measure the dimensions of the whole compressor construction. Make sure your measurements are very accurate, you can always double-check if you’re not too confident.

Next, you want to make the box itself. You can choose between concrete blocks, gypsum board, or any other fire-resistant material to avoid accidents.

Many people prefer to use concrete blocks with sand filling in the voids as it further enhances sound blocking.

After you’re done with the box, it’s now time to line the inner walls, including the top and bottom sides, with sound insulating materials. You can use foam, rubber pads, or other fabrics.

Whatever your end result is, it’s crucial that you provide your compressor with enough ventilation by installing a quiet fan or a cooling system. If you ignore this step, it’s very possible for the compressor to overheat and burst into flames, which never ends well.

5. Distance Yourself from the Compressor

This one’s a pretty logical solution to any noise problem, you just need to get away from the source!

Putting as much distance between you and your air compressor can greatly decrease the amount of sound you can actually hear. In fact, for every doubling of the distance you achieve, you cut down the noise level by 6 decibels.

So if you own an 80-decibel compressor and you move it from 10 meters to 20 meters away, you’ll only hear 74 decibels.

Additionally, the more barriers you place between yourself and the compressor, the less noise you’ll be able to hear. Walls are a terrific example of such barriers.

6. Check and Tighten any Loose Parts

As we already mentioned, loose screws or internal components can be the reason being all the exaggerated noises you’re hearing, which typically sound like rattling or banging.

This is particularly true when we’re talking about vibrating machines, such as air compressors, because bolts and screws tend to “loosen up” over time.

Other components including clamps, pulleys, and flywheel, may also be displaced after a while. So it’s best if you check the whole compressor set.

Even if it’s not the cause of the problem, checking and tightening all the loose ends will help you find the real culprit faster.

7. Keep the Air Filters Clean

Yes, something as harmless as an air filter may be causing your compressor to produce ridiculously loud sound, just because it’s not clean.

Filters are responsible for cleaning the air that’s going inside the compressor for storage. This means they keep out a lot of dust that’ll simply accumulate if you don’t remove it.

The dust build-up will eventually block the air intake system, making your machine run harder and louder.

You can avoid this situation by cleaning the air filters every 6 months or so.

Safety Tips

Almost all of our methods will have you making modifications to your air compressor, and as the rule goes when working on such heavy equipment, safety should be your number one priority.

This calls for extra caution while handling your compressor because pressurized air can be super dangerous. Here are some tips to stay safe:

- Be sure to first unplug and bleed the air tank before making any alterations

- Make sure you’re providing adequate ventilation

- Make sure you’re not overly restricting the air intake

- Never go above the maximum PSI (Pound-force per Square Inch) settings of the compressor

We hope this article has helped you reduce air compressor noise to an acceptable level. Thanks for reading.

As an Amazon Associate I may earn a small fee from qualifying purchases at no extra cost to you. This helps us run the site, so thanks for your support!

I have a small portable air compressor which makes so many noises during loading. I have fastened it with a proper bolt and gasket to the floor and tried to tighten all loose parts. Finally found the belt of the fan pully was a bit rubbed and as a consequence the motor vibrated a lot!

I’m glad you got to the bottom of it Perez, thanks for visiting our blog.